|

| Sampler made by Margaret Platt, 1736. Margaret was a cousin of the Platt brothers who founded Plattsburgh and the great-grandmother of Lucretia Maria and Margaret Davidson. |

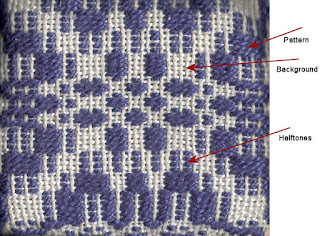

Until relatively recently, needlework skills were an essential part of female education. All girls learned basic sewing skills, and some pursued more advanced embroidery. The sampler emerged sometime in the 16th century and was originally a pattern record of stitches and techniques (the term sampler comes from the Latin exemplum, or example). Colonists brought this tradition of sampler-making to North America in the 17th century, though very few examples have survived from that period. By the 18th century, distinctive sampler styles were beginning to develop, identified with specific regions and often with particular schools or teachers. However, American samplers shared common elements: alphabets and numbers, religious or moral verses, names and dates (often in the form of a family record), floral motifs, landscape scenes including people, houses, and animals, and geometric patterns.

|

| Scenes from a Seminary for Young Ladies, ca. 1810-20 Saint Louis Art Museum |

|

| “Miss Godchild's First Sampler,” English print, 1793 |

A girl generally made her first sampler between the ages of five and nine. This would usually be a marking sampler, intended to teach basic sewing and literacy skills through the stitching of letters and numbers. In a time when household linens were extremely valuable, every sheet, napkin, pillowcase, and towel had to be marked with initials to ensure that it was returned safely from being sent out for laundering, and with numbers so that items could be rotated for even wear. If her education continued at a female academy, the young lady might then make a more decorative sampler or needlework picture. This piece might be part of an exhibition at the school, demonstrating her skill to family, friends, and local dignitaries, and would serve as an advertisement for the school. She would then bring the framed needlework home to be displayed as a sort of “diploma,” testifying to her educational and artistic accomplishments.

|

| Colonial Revival sampler, 1917 |

Sources:

Early works on samplers include Marcus B. Huish, Samplers and Tapestry Embroideries (1913) and American Samplers, published by the Massachusetts Society of the Colonial Dames of America in 1921. For recent scholarship, the works of Betty Ring, particularly Girlhood Embroidery and American Needlework Treasures, are invaluable.